https://doi.org/10.1140/epjp/s13360-025-06502-x

Regular Article

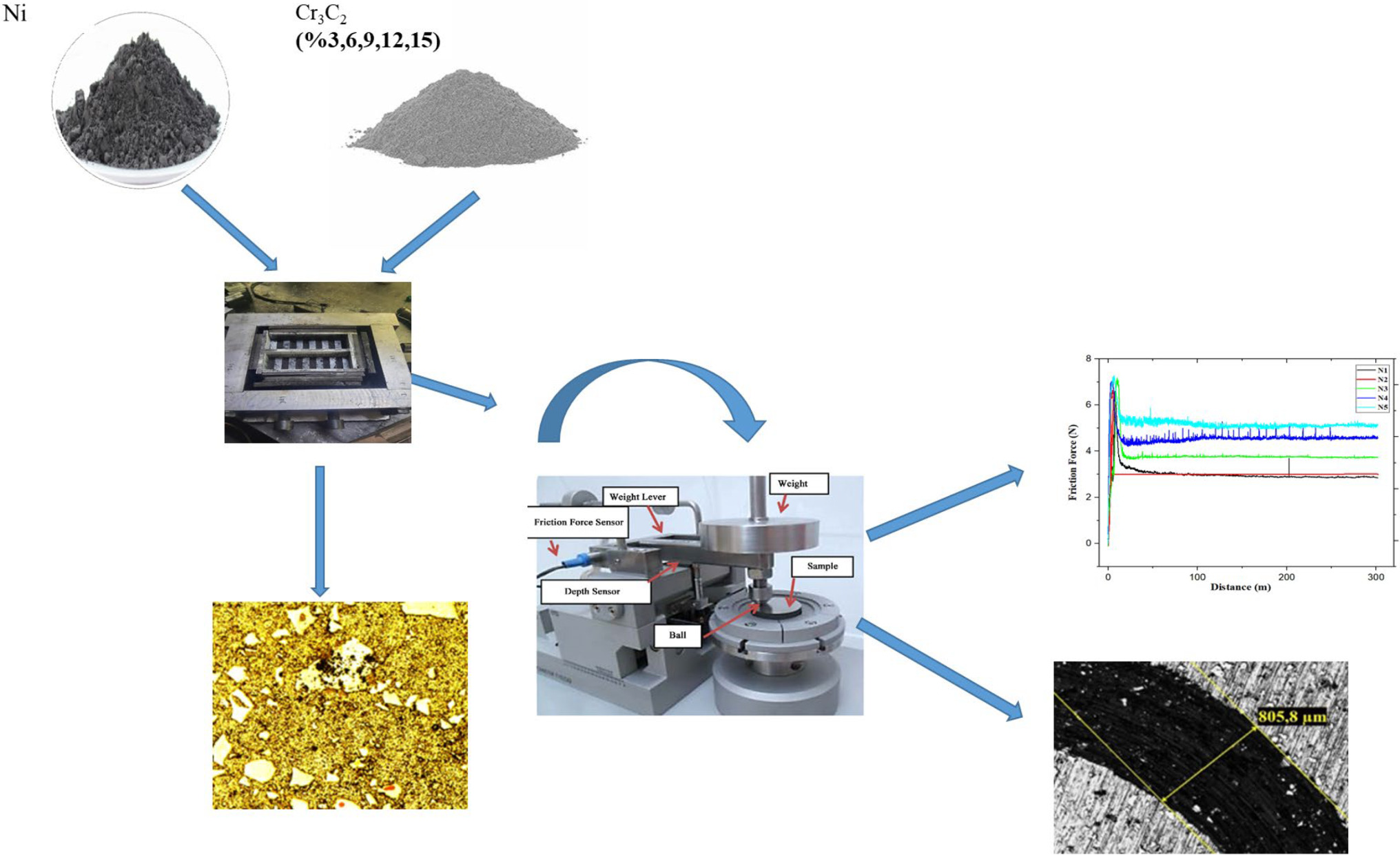

Characterization of Cr3C2/Ni ceramic–metal composites produced by direct resistance rapid hot pressing method

1

Department of Control and Automation, Borçka Acarlar Vocational School, Artvin Çoruh University, Artvin, Turkey

2

Department of Aircraft Maintenance and Repair, School of Civil Aviation, Faculty of Technology, University of Firat, Elazig, Turkey

3

Department of Aircraft Maintenance and Repair, School of Civil Aviation, Istanbul Nisantasi University, Istanbul, Turkey

Received:

5

February

2025

Accepted:

30

May

2025

Published online:

23

June

2025

The Cr3C2 phase of chromium carbides exhibits excellent corrosion resistance and low density, but vacancies in these materials sometimes limit their use in some applications. In order to expand the areas of use and further develop these materials, cermets containing metallic phases that provide better strength, hardness, and workability have been developed. This study examined the microstructure and mechanical properties of Cr3C2–Ni cermets fabricated through direct resistance rapid hot pressing. Cr3C2 and Ni powders were mixed in varying ratios, sintered, and analyzed using optical microscopy and X-ray diffraction for microstructural characterization. Mechanical properties were evaluated via Vickers hardness tests, density was measured using Archimedes' principle, and wear behavior was assessed. Results indicated that changes in Cr3C2 content significantly influenced mechanical properties and wear resistance, with the sample containing 18% Cr3C2 displaying superior strength and wear resistance. These findings highlight the potential of Cr3C2–Ni cermets in applications demanding robust and durable materials, representing a significant advancement in their development.

© The Author(s) 2025

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.